The rapid development of the hydrogen energy industry is propelling the Hydrogen Compressor market into a golden period, igniting a race encompassing technology, market presence, and strategy. The global hydrogen compressor market is demonstrating robust growth. Industry data indicates that the global hydrogen compressor market size reached USD 2.06 billion in 2024 and is projected to increase to USD 3.11 billion by 2032, representing a compound annual growth rate (CAGR) of 5.45% during this period.

This growth is primarily driven by the accelerated global energy transition and the large-scale construction of hydrogen infrastructure. The Asia-Pacific region dominates the global market, holding a substantial share of 52.43%. China, as the world's largest hydrogen producer and consumer, has become the core growth engine for this market.

Market Overview: Asia-Pacific Leads, China as the Growth Engine

As a core component of the hydrogen industry chain, the demand for hydrogen compressors is closely linked to the development of the hydrogen energy sector. Hydrogen compressors increase hydrogen pressure, allowing it to occupy less space and facilitating easier storage and transportation, making them crucial for the hydrogen fuel industry. Countries worldwide are continuously investing in hydrogen infrastructure and other clean energy projects to achieve net-zero emission targets. According to the Hydrogen Council, by 2030, 359 announced hydrogen-related projects globally represent a total investment of USD 500 billion across the entire value chain.

Regionally, the Asia-Pacific region accounts for over half of the global hydrogen compressor market. This region is a major consumer of hydrogen in industries such as petrochemicals, chemicals, and oil & gas, which sustains demand for hydrogen compression units. Significant investments in hydrogen fuel cell technology and infrastructure by Japan, South Korea, and China are further driving market growth in the region.

Competitive Landscape: International Giants Dominate, Chinese Players Break Through

The global hydrogen compressor market is led by several internationally renowned companies, including Siemens, Atlas Copco AB, and Mitsubishi Power, among others. Leveraging deep technological expertise and global market presence, these firms hold significant market shares. A key strategic focus for these companies is new product development to continuously strengthen their market positions.

For instance, Atlas Copco announced in January 2024 the acquisition of HYCOMP, a company specializing in high-pressure oil-free compressors and boosters, thereby expanding its product portfolio.

Facing the technological advantages of international giants, Chinese hydrogen compressor manufacturers are achieving import substitution through continuous innovation. Yantai Dongde Industrial Co., Ltd. has conquered ionic liquid sealing compression technology, launching the world's first ionic liquid seal compressor. With an exhaust pressure exceeding 100 MPa and a single-unit displacement of 50,000 standard cubic meters, it breaks the long-term foreign monopoly in this field. Utilizing a crankshaft connecting rod structure and circulating ionic liquid sealing technology, this equipment achieves zero hydrogen leakage within the compression chamber, making it applicable not only to the hydrogen industry but also to other gas sectors.

Fengdian Jinkaiwei (Suzhou) Compressor Co., Ltd. has successfully developed China's first 90 MPa diaphragm compressor, achieving technological independence and a breakthrough in high-pressure grade core equipment for hydrogen refueling stations, with overall performance reaching international advanced levels. Under an inlet pressure of 12.5 MPa, this compressor achieves an exhaust pressure not less than 87.5 MPa and an exhaust flow rate not less than 200 Nm³/h. It has also completed a rigorous 500-hour cumulative trouble-free operation test.

Market Drivers: Policy and Demand as Dual Growth Engines

Policy Support

Governments worldwide are actively introducing policies supporting hydrogen energy, creating a favorable environment for the hydrogen compressor market. China's 14th Five-Year Plan outlines strategic priorities for hydrogen energy technology innovation and industrial decarbonization. The European Commission has formulated a strategy aimed at making hydrogen a decarbonization solution, planning to install 40 GW of renewable hydrogen electrolyzers by 2030 to produce 10 million tons of hydrogen. Local governments are also actively following suit. For example, Chongqing municipality offers a subsidy of 30% of the actual investment for hydrogen refueling stations included in the city's overall plan and put into operation, with a maximum subsidy of RMB 3 million per station.

Fuel Cell Vehicle Adoption

The rapid development of Fuel Cell Electric Vehicles (FCEVs) provides strong momentum for the hydrogen compressor market. As countries globally tighten vehicle emission regulations, the automotive industry is increasingly turning to FCEVs. These vehicles emit only water vapor as a byproduct, effectively addressing air pollution and climate change issues. Widespread adoption of FCEVs requires the establishment of robust hydrogen refueling infrastructure, including hydrogen compressor stations. Hydrogen compressors play a crucial role in facilitating the compression and storage of hydrogen, thereby supporting the efficient refueling of FCEVs. Consequently, the growing sales of FCEVs offer significant expansion space for the hydrogen compressor market.

The Chinese Path: Technological Breakthroughs and Industry Chain Synergy

Facing broad market prospects, Chinese hydrogen compressor enterprises need to strategize across multiple dimensions to seize the initiative in global competition.

Breaking Technological Bottlenecks

Chinese companies need to continuously tackle high-performance core technologies. For example, Dongde Industrial, through R&D into circulating ionic liquid sealing technology that seals, lubricates, and cools piston rings in conjunction with sealing components, has achieved zero hydrogen leakage within the compression chamber. This not only solves hydrogen handling challenges but is also applicable for pressurizing toxic, hazardous, flammable, and explosive special gases. Fengdian Jinkaiwei has developed a series of core components, including 90 MPa dedicated high-pressure combined membrane heads, high-pressure hydrogen valves, anti-shock anti-jamming high-pressure oil overflow valves, and high-pressure special-shaped closed-loop metal sealing rings, breaking foreign technological monopolies.

Reducing Costs and Perfecting the Industry Chain

Hydrogen compression systems require significant upfront investment, including equipment purchase, installation, and infrastructure development. The initial procurement cost of hydrogen compression equipment accounts for approximately 30%-40% of the total hydrogen compression cost. Chinese companies can reduce product costs through scaled-up production and supply chain localization. Simultaneously, by fostering synergistic development with upstream and downstream enterprises across the entire hydrogen industry chain encompassing "production, storage, transportation, refueling, and utilization," they can build a complete industrial ecosystem.

Expanding Application Scenarios

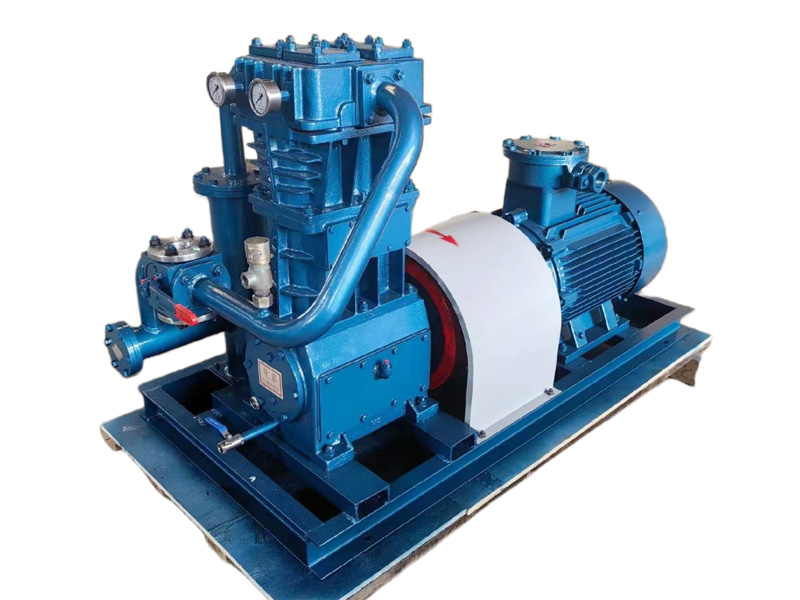

Beyond traditional industrial applications and hydrogen refueling stations, Chinese hydrogen compressor enterprises should actively explore new application fields. Based on its core ionic liquid seal compressor technology, Dongde Industrial has developed an integrated hydrogen production and refueling station compressor. This integrates the functions previously requiring two separate units into one, with an exhaust pressure of 45 MPa, making it better suited for high-capacity refueling station needs. Through skid-mounted integrated design, Dongde Industrial has also launched the nation's first ionic liquid seal compressor unit, significantly enhancing equipment flexibility and scenario adaptability.

Looking Ahead

As the global energy transition accelerates, the hydrogen compressor market will continue to expand. Driven by both policy support and technological innovation, Chinese enterprises are expected to achieve more breakthroughs in high-end fields such as ionic liquid seal compressors and 90 MPa and above diaphragm compressors, gradually evolving from followers into leaders in global hydrogen equipment technology. The rise of Chinese hydrogen compressor companies is not only about market share but also represents a crucial manifestation of national energy security and high-end equipment manufacturing capability.